BRADFORD — The village of Bradford is seeing new technology and up-to-date equipment in use at its new Water Treatment Plant.

The new plant, located on Klinger Road next to the old plant, went online in the middle of January. It was a five-year process to reach this milestone, including approximately eight months of construction. The new plant was created to replace the aging, old plant — built between the 1950s and 1960s — and its outdated equipment.

The village receives its water from three wells, which Water Treatment Plant Supervisor Jay Roberts said they are also updating with new pumps.

The water goes through the aeration tank outside of the plant, which Roberts explained oxidizes dissolved metals like iron and manganese out of the water. Those substances can then be removed in the filtration process.

From the aeration tank, the water goes to a detention tank and through pre-chlorination, which is a new process to the plant. Both the pre-chlorination and post-chlorination processes disinfect the water.

The water plant also features new filters, new water softeners, new high-service pumps, and a new control panel.

“This is brand-new,” Roberts said about the control panel. The control panel features a touch screen that monitors all of the plant’s processes. Roberts is also able to monitor the plant even when he’s not there since the control panel connects with other devices.

The plant also has a testing area where Roberts tests the water quality everyday.

“I test for chlorine, hardness, and pH,” Roberts said.

The new plant for Bradford — with a population of just over 1,800 people — cost approximately $2.1 million. For comparison, the new Water Treatment Plant in Piqua — with a population of approximately 20,906 people — cost approximately $36 million.

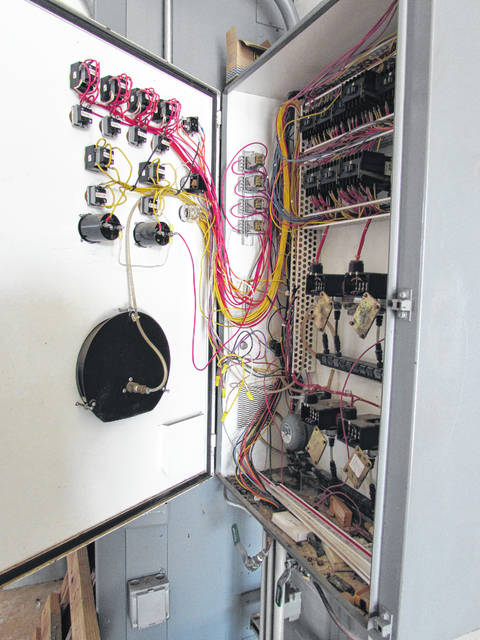

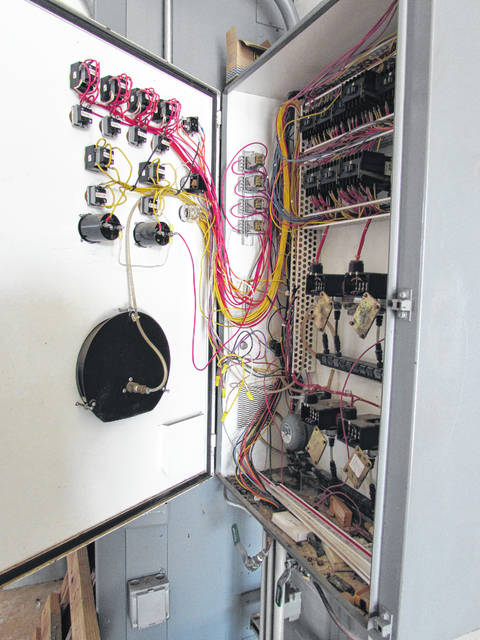

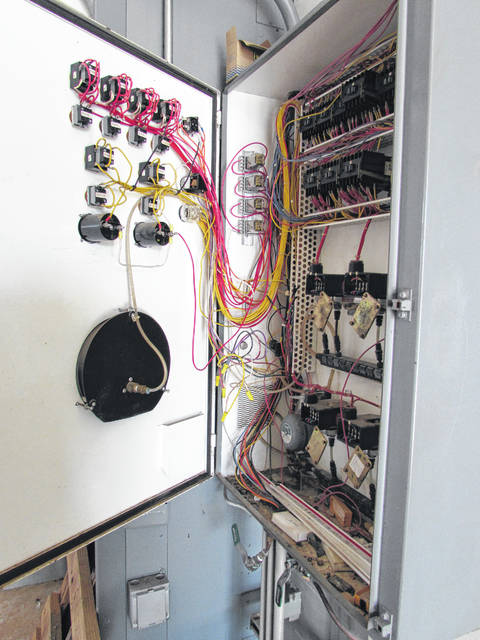

What the village is replacing, though, is a 50-year-old plant with outdated and unsafe technology, including a water line that ran through a high-voltage electric panel and a chlorine room that officials from the Environmental Protection Agency would not enter.

While the outside of the old plant might look nice, the inside tells a different story. Walking by the old filters in the old plant, Roberts is able to point out sections of the filters that broke off and needed to be welded back together. Roberts spoke of incidents in which the corner of a filter broke off and shot water undergoing about 80 pounds of pressure across the plant.

“That’s a problem,” Roberts said. “Our tanks were so deteriorated that at any moment, our tanks could have exploded.”

The old equipment would also shake the plant to the point of creating indentations on the different parts of the concrete wall. Roberts said that it could feel like an earthquake.

The electric panel also featured technology from the 1960s and the 1970s, including water running through the electrical grid.

“There’s a water line in our electric panel,” Roberts said. “Obviously not a good situation.”

The old plant also used to have a chlorine room to treat the village’s water.

“We used to use gas,” Roberts said. He added that when officials from the EPA would come to inspect the plant, they would not enter that chlorine room because it was too dangerous.

Now, the new plant’s up-to-date technology and equipment removes the need for quick fixes or unsafe conditions.

“The time had come,” Roberts said.

The new plant can also sustain population growth within the village and be added to if needed.

What residents will notice the most on a day-to-day basis, though, will be the quality of the water remaining consistent.

“More than quality, they’ll see a consistency,” Roberts said.